CARATTERISTICHE_TECNICHE: NOT FOUND

CORE COVER

Resistance to peak temp. 140 °C 380 °C

Tear strength 48,1 gr/den 31,4 gr/den

Friction coeff. 0,06 0,09

Grip winch/stopper moderate good

Smoothness excellent optimal

Abrasion resistance optimal optimal

Specific weight 0,97 gr/cm3 1,41 gr/cm3

Continuous work resist. optimal optimal

Color variants large moderate

Resistance to peak temp. 140 °C 380 °C

Tear strength 48,1 gr/den 31,4 gr/den

Friction coeff. 0,06 0,09

Grip winch/stopper moderate good

Smoothness excellent optimal

Abrasion resistance optimal optimal

Specific weight 0,97 gr/cm3 1,41 gr/cm3

Continuous work resist. optimal optimal

Color variants large moderate

UTILIZZO: NOT FOUND

- High load halyards

- Control line

- Control line

RICHIEDI_INFO: NOT FOUND

GAMMA_COLORI: NOT FOUND:

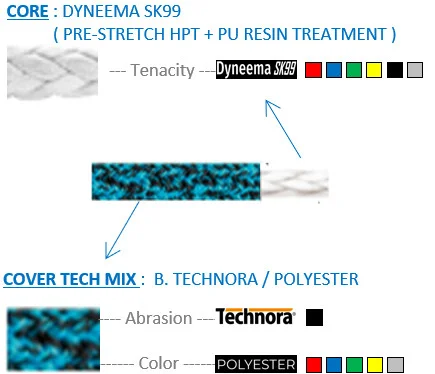

CORE DYNEEMA SK99 XTR

The excellent creep qualities combined with a tenacity of 43.2 cn/dTex and a modulus of 1.590 cn/dTex make it possible to build an extremely resistant and reactive line, dedicated to maneuvers subjected to high dynamic loads.

Thanks to the reduced specific weight of 0.974 kg/dm3 the rope is extremely light, while the protective treatment with a mix of polyurethane resins makes it water-repellent and highly resistant to wear.

The hot pre-stretch treatment called XTR takes the diameter/load ratio to the extreme by reducing the section and at the same time increasing the breaking load.

COVER BLACK TECHNORA / POLYESTER

It is a technical cover dedicated to high loads, temperatures and frictions.

Thanks to the Black Technora inserts, the resistance to abrasion and continuous work is excellent.

The high temperature tolerance point is excellent, guaranteeing a peak resistance of 380 °C.

The friction coefficient of 0.12 gives excellent grip both in the hand and on winches and stoppers.

The cover's tenacity of 16.5 cN/dTex guarantees good efficiency on winches and chokes.

The color range is wide thanks to the polyester components which allow the maneuvers to be easily recognisable.

The excellent creep qualities combined with a tenacity of 43.2 cn/dTex and a modulus of 1.590 cn/dTex make it possible to build an extremely resistant and reactive line, dedicated to maneuvers subjected to high dynamic loads.

Thanks to the reduced specific weight of 0.974 kg/dm3 the rope is extremely light, while the protective treatment with a mix of polyurethane resins makes it water-repellent and highly resistant to wear.

The hot pre-stretch treatment called XTR takes the diameter/load ratio to the extreme by reducing the section and at the same time increasing the breaking load.

COVER BLACK TECHNORA / POLYESTER

It is a technical cover dedicated to high loads, temperatures and frictions.

Thanks to the Black Technora inserts, the resistance to abrasion and continuous work is excellent.

The high temperature tolerance point is excellent, guaranteeing a peak resistance of 380 °C.

The friction coefficient of 0.12 gives excellent grip both in the hand and on winches and stoppers.

The cover's tenacity of 16.5 cN/dTex guarantees good efficiency on winches and chokes.

The color range is wide thanks to the polyester components which allow the maneuvers to be easily recognisable.

The following table shows the technical characteristics of the DYNEEMA SK99 XTR-PU rope with mixed sock in Black Technora / Polyester

| core : cover : |

DYNEEMA SK99 XTR-PU BLACK TECHNORA / POLIESTERE |

|

| Section | B.L. | Weight |

| mm | daN | gr/mt |

| 1 | - | - |

| 1,5 | - | - |

| 2 | 300 | 4,6 |

| 2,5 | 450 | 5,7 |

| 3 | 580 | 7,6 |

| 3,5 | 940 | 9,3 |

| 4 | 1.250 | 12,5 |

| 5 | 2.150 | 19,2 |

| 6 | 2.900 | 26,4 |

| 7 | 4.050 | 38,5 |

| 8 | 4.550 | 50,5 |

| 9 | 5.150 | 61,3 |

| 10 | 7.900 | 72,0 |

| - | - | - |

| 12 | 11.950 | 102,5 |

| - | - | - |

| 14 | 14.600 | 137,9 |

| - | - | - |

| 16 | 18.500 | 182,8 |

| 18 | 25.200 | 215,2 |

| 20 | 26.600 | 269,2 |

The average values indicated are obtained from tests in the Benvenuti company laboratory on new line and may be changed without any notice. Other diameters are available on request. The static load of the rope must not exceed 20% of the breaking loads indicated in the table. The knot affects the breaking load with reductions of up to 60%. Splicing increases the diameter approximately 1.5 times. Exposure to atmospheric agents determines reductions in the breaking loads of the ropes, depending on the intensity and duration of the same and also on the composition and construction of the product.